The Power of Real-Time Monitoring: Building Resilience in Critical Sectors

How IT/OT Monitoring Minimises Downtime, Enhances Operations, and Secures Business Continuity

Picture a manufacturing plant grinding to a halt during peak production or a power grid failure plunging entire cities into darkness—this is the critical intersection of IT and OT integration, where efficiency meets resilience.

How Do We Define IT and OT?

As industries become increasingly reliant on the seamless integration of IT (Information Technology) and OT (Operational Technology) systems, the pressure to ensure continuous and efficient operations has never been greater.

Information Technology (IT) refers to the use of systems, networks, and software to process, store, and share digital information. It focuses on data, ensuring cybersecurity, and supporting business processes. Operational Technology (OT), on the other hand, encompasses the hardware and software that monitor and control physical devices, systems, and processes, such as those found in manufacturing plants, utilities, and critical infrastructure. IT focuses on managing data and applications, while OT ensures the safe and efficient operation of physical systems. The increasing convergence between the two enables smarter and more interconnected systems.

Why is This Important?

Real-time monitoring is becoming increasingly critical, driven by several secular trends. First, digital transformation and cloud adoption are accelerating rapidly. Cloud spending as a percentage of IT budgets has doubled, growing from approximately 5% in 2020 to 10% in 20241.

This rapid growth has also introduced significant complexity, driven by the proliferation of technologies, the increasing size of processing and compute units, and the higher frequency of changes in underlying software. As a result, monitoring platforms that can seamlessly connect to and manage all IT and OT assets are now essential to navigating this complexity.

Real-time monitoring for operational technology (OT) assets is even more critical due to the inherent challenges and complexities unique to OT environments. Unlike IT systems, OT systems are intricately tied to physical processes, where disruptions can lead to production downtime, safety risks, or even physical damage to equipment. Traditional IT monitoring tools, which rely on network scans and invasive techniques, can inadvertently cause malfunctions in OT systems. Adding to this complexity, OT assets frequently rely on proprietary communication protocols and require specialized discovery and monitoring approaches.

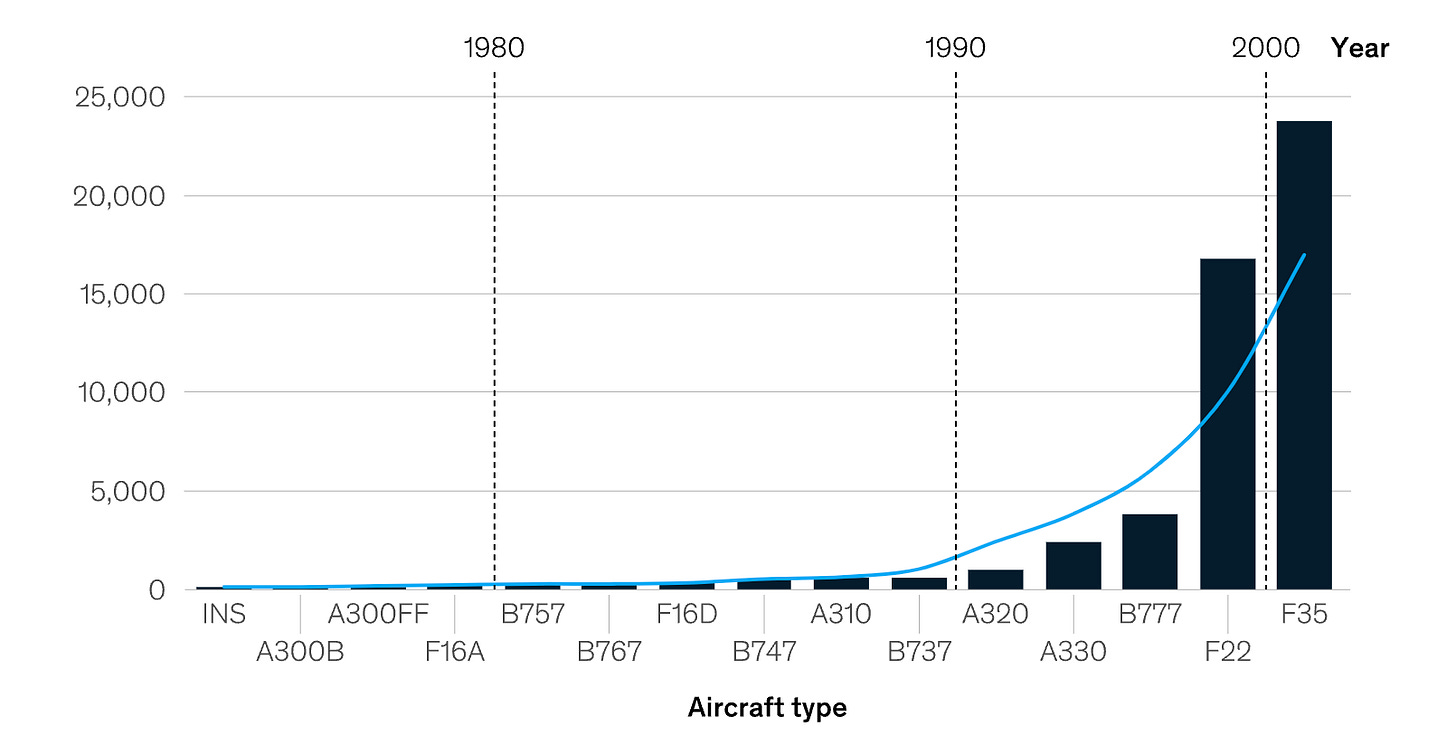

This rising complexity mirrors broader trends across industries. As seen in the charts below, in automotive systems, software complexity has quadrupled over the past decade, while productivity has only modestly increased. Similarly, in aerospace systems, the growth in software complexity—measured in thousands of lines of source code —has skyrocketed, with advanced platforms like the F-35 requiring over 25 million lines of code2. These trends underscore the growing need for tailored solutions that can operate within these increasingly intricate environments.

To navigate these constraints, real-time monitoring systems must be engineered to maintain the reliability, safety, and efficiency of OT operations while minimizing risks. This makes them indispensable for ensuring seamless operations in industries where precision and continuity are non-negotiable.

From manufacturing floors producing automotive components to power grids ensuring uninterrupted energy supply, from hospitals running life-critical medical equipment to retail chains managing just-in-time inventory systems, from underground transport systems to airports, real-time monitoring has emerged as a critical tool for asset operators. This technology ensures that unplanned downtime is minimized, enabling factories to meet production deadlines, utilities to maintain grid reliability during peak demand, hospitals to safeguard patient care, and retailers to avoid stockouts or system failures that disrupt customer experiences—all while protecting overall business continuity.

The High Cost of Unplanned Downtime

Unplanned downtime isn’t just an inconvenience—it’s a huge economic cost across sectors. According to research3, it costs Fortune Global 500 Companies 11% of their yearly turnover. The cost of a lost hour ranges from $39,000 for factories that produce fast moving consumer goods (FMCG) to over $2 million in the automotive industry.

Disruptions in OT systems managing energy grids can result in outages that cost utility providers millions, not to mention the social and economic ripple effects.

Downtime in hospitals—impacting imaging equipment, ventilators, and laboratory systems—costs an average of approx. $500,000 per hour, with potentially life-threatening consequences.

IT/OT failures in retail can halt point-of-sale systems, disrupt inventory management, and cripple e-commerce platforms during peak sales hours, leading to substantial revenue losses and reputational harm.

These high economic costs highlight why real-time monitoring is no longer optional but an essential investment for businesses striving to ensure continuity, resilience, and long-term competitiveness.

How Real-Time Monitoring Transforms Operations

Real-time monitoring is the continuous observation, analysis, and reporting of data as it happens. It tracks parameters, activities, or processes instantly, enabling swift responses and decisions based on the latest information. It enables operators to move from reactive to proactive asset management. Here’s how it makes an impact:

1. Proactive Anomaly Detection

Real-time monitoring systems continuously collect and analyze data from IT/OT assets, identifying anomalies and potential red flags before they escalate into critical failures. For example:

Industrial Production: IoT sensors detect abnormal vibrations in manufacturing equipment, indicating wear and tear that can be addressed before a breakdown halts production.

Power Grids: Real-time data from substations can identify overheating transformers, allowing for timely interventions to prevent outages, which then unfortunately create much more severe problems across large regions.

2. Predictive Maintenance

Predictive analytics powered by real-time monitoring systems enable operators to replace or repair components before failure occurs. According to a study4, predictive maintenance increases productivity by 25%, reduces breakdowns by 70% and lowers maintenance costs by 25%.

3. Operational Visibility

Centralized dashboards aggregate real-time data across assets, offering operators a holistic view of operations. This visibility improves decision-making and accelerates response times. For example, monitoring inventory and sales data in real time allows large retailers to optimize stock levels and avoid costly overstock or stockouts. In manufacturing, a unified view of assembly line performance helps identify bottlenecks and improve efficiency.

4. Resilience Against Cyber Threats

As IT/OT integration increases, so does vulnerability to cyberattacks. Real-time monitoring systems enhance cybersecurity by detecting potential threats early and enabling rapid responses to mitigate risks. This is especially critical in sectors like energy supply, where cyberattacks can have far-reaching consequences.

Closing Thoughts

Real-time monitoring is not a nice to have - it’s a necessity. It is not just about efficiency either - it’s about resilience. By enhancing visibility, predicting potential failures, and improving resilience, organizations can focus on long-term growth rather than reacting to crises. As we continue to integrate IT and OT systems, real-time monitoring will remain the cornerstone of resilience in our increasingly complex operational environments.

Datadog Investor Day Presentation (page 6)

https://assets.new.siemens.com/siemens/assets/api/uuid:3d606495-dbe0-43e4-80b1-d04e27ada920/dics-b10153-00-7600truecostofdowntime2022-144.pdf

https://www.deloitte.com/content/dam/assets-zone2/de/de/docs/about/2024/Deloitte_Predictive-Maintenance_PositionPaper.pdf